PLASTIC PROFILE EXTRUSION

Frequently Asked Questions

Quoting and Costs of Plastic Extrusions

Formtech

General

Tolerances

Each dimension on your plastic extruded profile has a tolerance, but what is a tolerance and why is it important? A tolerance provides a manufacturer allowance for a specific dimension to be larger or smaller than nominal, but still be within specification. For instance, a length tolerance may be 48.00” +/- 0.5”. This means that the length of the extrusion can be anywhere between 47.50” or 48.5” and still be deemed acceptable to the manufacturer and to the user.

Tolerances are determined based on several factors:

- Application of the extrusion (fit and function)

- Manufacturing capabilities

- Cost

Application of the Extrusion (Fit and Function): Any product must work in its application, which may include a need for specific functionality or the need for the product to work with mating parts.

Manufacturing Capabilities: New technologies in extrusion equipment, extrusion tooling, and thermoplastic materials allow for tight tolerances to be held in the plastic extrusion process. For instance, changing output rates to improve control of the product during the extrusion cooling process, adding vacuum calibration, or using high quality plastic compounds are options that can help tighten tolerances.

Cost: If tolerances are extremely tight, some work may need to be done offline, contributing to higher costs resulting from increased time needed to manufacture the product and/or increase handling of the product. Balancing the need for tight tolerance and economic considerations is important when designing a plastic extrusion.

Certainly, tolerances on plastic extrusions impact fit and function, and contribute to overall performance of the plastic part. But, at what cost? Technology has progressed in plastic extrusion equipment, extrusion tooling, thermoplastic materials and even methods of measurement. There are, however, limitations to tolerances on the product before the cost of the custom extrusion is impacted. Even with advancements in extrusion technology, tolerances that are extremely tight are one of the leading contributing factors in increased costs. In the design of a system that includes custom plastic extrusion, it is a best practice to consider which areas of the profile need to be maintained as critical, and how tightly they need to be held from a tolerance perspective based on the attended use. When a custom plastic profile extrusion company is dealing with extremely tight tolerances, we are forced to look at available options to control the cooling and sizing of the profile. Some options are listed below:

- Reducing output rate for increased control over the extrusion cooling process

- Additional vacuum calibration to keep the extruded plastic profile, at an increased overall tool cost

- More expensive compounds to allow better control over the plastic extrusion

All the above options can improve tolerance control, but they do increase the cost of the end product. There is definitely a balance between tolerances and economics when it comes to custom profile extrusion. The extrusion must perform for the intended use, but design for manufacture and making sure tolerance limitations are reviewed during the design of the plastic profile as part of the overall system can save you money on the finished extruded plastic part(s).

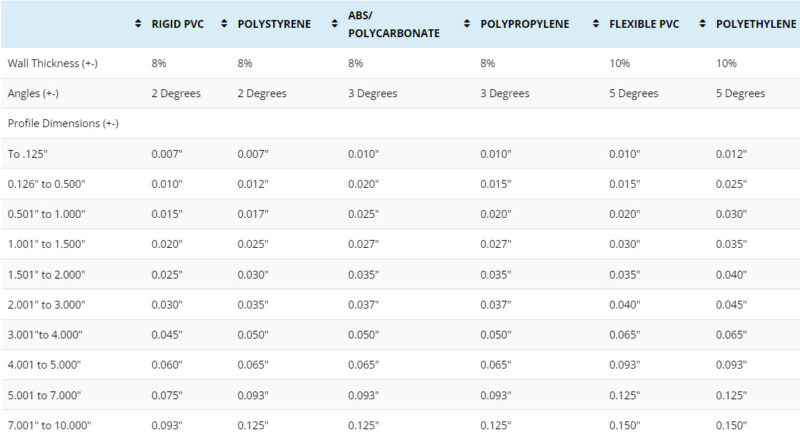

What Tolerances are Typical? The below table details typical tolerances for a variety of thermoplastic materials. This table is for reference only.